In recent years, the quest for better-performing materials in the knife-making industry has led to innovative alloys like powder metallurgy Magnacut steel. Known for its exceptional toughness, corrosion resistance, and edge retention, this steel owes much of its success to powder metallurgy. This process enhances its composition and grain structure, elevating Magnacut steel’s performance to new heights.

Understanding the Basics: What is Powder metallurgy?

Powder metallurgy is an intriguing branch of materials science and engineering that deals with the production and manufacturing of metal powders and their subsequent conversion into solid objects. By taking metals in their powdered form, this process allows for the creation of components that are often unfeasible to produce using customary techniques like casting or forging. Imagine baking a cake, but instead of flour and sugar, you’re working with fine metal particles. The powdered metals are compacted into a desired shape and then heated to bind the particles together without reaching the melting point. This technique is particularly valuable for creating intricate designs and achieving precise control over material properties.

One of the most notable advantages of powder metallurgy is its ability to produce highly uniform and stable materials. This uniformity is crucial for industries requiring components with consistent quality,such as aerospace,automotive,and electronics. Moreover, the process minimizes waste, as excess powder can frequently enough be reused in subsequent manufacturing cycles. **How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance** is a fascinating exploration of how this technique contributes to creating high-performance materials with enhanced durability and resilience. By allowing for meticulous customization of the alloy’s composition, powder metallurgy ensures that each batch meets stringent standards.

Another remarkable feature of powder metallurgy is its versatility in producing both simple and complex geometries. The ability to create components with intricate internal structures without the need for machining is particularly advantageous for industries were weight reduction and material efficiency are paramount.The process also facilitates the incorporation of multiple materials, offering the potential for composite materials with tailored properties. This versatility in design and composition is how powder metallurgy continues to revolutionize the manufacturing world. It’s also a key factor in **How powder Metallurgy Helps Magnacut Steel Achieve Superior Performance**,offering enhanced attributes like wear resistance and increased tensile strength.

In terms of environmental impact, powder metallurgy is often a more sustainable option compared to traditional metalworking. The energy required for the sintering process, where metallic powders are heated and bonded, is generally lower than that needed for melting and casting metals. This energy efficiency not only reduces the overall carbon footprint of manufacturing but also lowers production costs. Additionally, since the process can be tailored to use minimal material without sacrificing strength or durability, it aligns well with the push towards eco-pleasant manufacturing practices.It’s fascinating to consider **How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance** by reducing environmental impact while delivering high-quality results.

For those curious about cutting-edge materials technology, studying powder metallurgy offers a glimpse into the future of manufacturing. The process’s ability to produce parts that are not only robust and lightweight but also cost-effective and environmentally friendly is setting new standards for industries across the globe. The ongoing advancements in this field, including the development of specialized alloys like Magnacut steel, highlight its importance in modern engineering. By understanding **How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance**, one can appreciate the meticulous blend of science and innovation that drives the evolution of materials.

the Science Behind Magnacut Steels Unique Composition

When diving into the fascinating world of steel composition, Magnacut steel stands out due to its unique blend of elements. This exceptional alloy is crafted meticulously to offer the best of both durability and flexibility, making it a preferred choice for a variety of applications. What sets it apart is the precise balance of carbon, chromium, vanadium, and nitrogen. Each component plays a pivotal role in defining the characteristics of the steel.The addition of chromium, for example, enhances its corrosion resistance, while carbon contributes to hardness. The magic, however, lies in the synergy between these elements, which elevates its performance considerably.

One of the key mechanisms that enhance Magnacut steel’s properties is Powder Metallurgy. This advanced process involves blending powdered metals to create a uniform and controlled composition. **How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance** is through the elimination of impurities and achieving a fine-grained structure that improves the alloy’s toughness and edge retention. Unlike traditional steel-making processes that can lead to uneven distributions of alloying elements, powder metallurgy ensures a consistently high-quality product.

Magnacut steel’s microstructure is another critical factor that contributes to its unique properties. The fine carbide structure formed during the powder metallurgy process results in improved wear resistance. This is particularly critically important in applications where the steel is subjected to high abrasion and impact. The presence of vanadium in the composition further aids in the formation of vanadium carbides, which significantly enhance the wear resistance and cutting performance of the steel. The finely distributed carbides prevent the material from chipping or breaking, providing a longer-lasting edge.

Furthermore, the incorporation of nitrogen into Magnacut steel’s composition is a game-changer. Nitrogen not only increases the hardness of the steel but also enhances its resistance to corrosion and wear.This is achieved without compromising toughness, which is often a trade-off in traditional steel-making practices. The role of nitrogen is crucial, as it allows the steel to maintain its structural integrity under various environmental conditions. The advanced control over the nitrogen content through powder metallurgy ensures **How Powder Metallurgy Helps Magnacut steel Achieve Superior Performance**,even when exposed to harsh conditions.

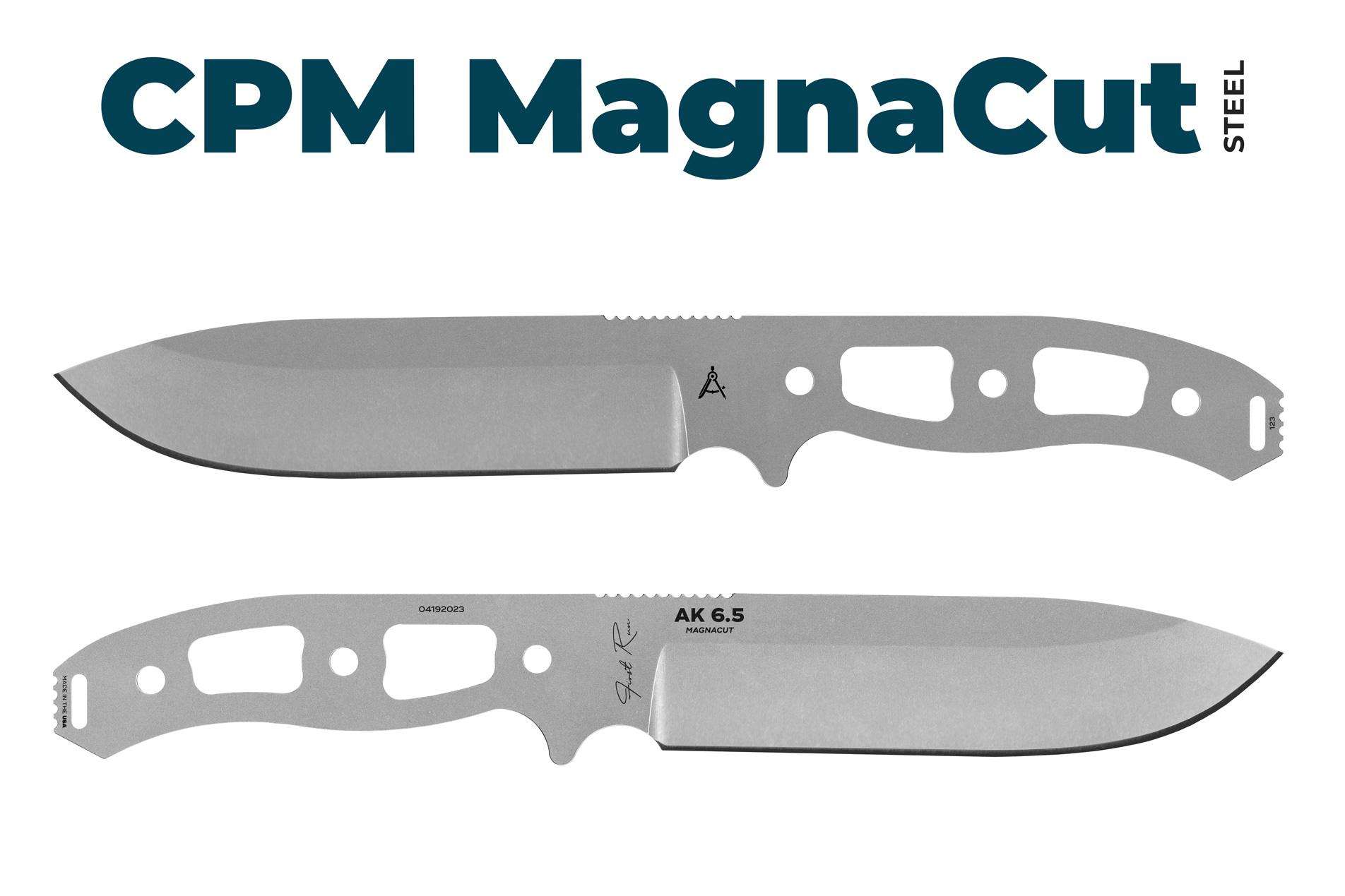

In terms of practical applications, Magnacut steel is a favored choice for high-performance knives and cutting tools. Its ability to maintain a sharp edge over extended periods makes it highly sought after by professionals and enthusiasts alike. The unique composition of Magnacut steel also lends itself well to customization, allowing manufacturers to tailor the alloy to specific needs. Whether it’s for culinary knives, outdoor tools, or industrial equipment, the versatility of this steel is unmatched.

the exceptional qualities of Magnacut steel stem from its distinctive composition and the sophisticated process of powder metallurgy. This combination results in a high-performance material that offers superior hardness, toughness, and corrosion resistance. As technology advances, **How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance** will continue to evolve, pushing the boundaries of what is possible in the realm of steel manufacturing and expanding its applications even further.

How Powder Metallurgy Enhances the Performance of Magnacut Steel

One of the most pivotal elements of powder metallurgy is the **uniformity** it brings to the table.in conventional steel-making processes, achieving a consistent distribution of alloys across the steel matrix can be challenging. Though, with powder metallurgy, the creation of steel begins at the microscopic level where powdered metal particles are meticulously blended. This ensures that each particle contains the desired alloy composition. As an inevitable result, Magnacut steel exhibits a **homogeneous microstructure** that contributes to its consistent mechanical properties. This uniformity augments the steel’s performance, making it extraordinarily reliable under stress.

Beyond uniformity, the **flexibility** of powder metallurgy is another advantage. This method allows for precise control over the composition and density of the final product. When applied to the production of Magnacut steel, this flexibility ensures that specific properties can be tailored to meet precise requirements.for instance, by altering the powder blend, manufacturers can enhance particular attributes such as toughness or hardness. This adaptability showcases How Powder Metallurgy Helps Magnacut Steel Achieve Superior performance by allowing it to excel in applications requiring specific traits.

Furthermore, powder metallurgy facilitates **fine-tuning** of the particle sizes used in the steel-making process. The ability to utilize ultra-fine powders results in a denser and more compact product. This density is crucial for Magnacut steel, as it affects the material’s wear resistance and overall durability. The finer the particle, the tighter the grain structure, which in turn minimizes wear and tear during usage. This aspect is particularly beneficial for cutting tools and knives, where maintaining a sharp edge is paramount.

Along with creating a densely packed material, powder metallurgy also allows for the incorporation of **unique alloying elements** that might be challenging to blend using traditional methods. This opens the door for innovation in material science, as new alloys can be developed with enhanced properties. For Magnacut steel, this means an increased ability to resist oxidation and other forms of environmental degradation. **How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance** is evident here, as these enhanced properties allow the steel to maintain its integrity and performance in challenging conditions.

the **sustainability** aspect of powder metallurgy cannot be overlooked. The process is inherently more efficient than traditional melting and casting methods, leading to less material waste and lower energy consumption. This efficiency is not only beneficial from an environmental perspective but also contributes to the cost-effectiveness of producing high-quality Magnacut steel. The reduced waste and energy requirements mean that resource allocation can be optimized, ensuring that Magnacut steel remains an economically viable choice for industries seeking high-performance materials.

Strength and Durability: Key benefits of Using Powder Metallurgy

When it comes to crafting materials that need to withstand the test of time, both in terms of physical stress and environmental conditions, powder metallurgy (PM) comes into play as a game-changer. This process involves compacting metal powders into a desired shape and heating them to form a solid piece. the result? Components that boast remarkable **strength** and **durability**. Through this technique, manufacturers can produce parts that offer consistent performance and longevity, making it a preferred choice for industries ranging from automotive to aerospace. One of the standout aspects of PM is its ability to enhance materials, such as in the case of How powder Metallurgy Helps Magnacut Steel Achieve superior Performance, integrating finer microstructures that contribute to its robustness.

A significant advantage of powder metallurgy is its capacity to produce materials with exceptional **tensile strength**. Through controlled processing, the microstructure of the material is refined, enhancing its ability to withstand stress without breaking. This fine-tuning of material properties is essential for applications where failure is not an option, such as in the manufacturing of precision gears and high-performance engine components. Moreover, PM allows for the incorporation of various alloying elements that can tailor the mechanical properties of the final product, optimizing it for specific applications. In instances like How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance, the ability to refine the steel’s grain structure results in higher strength compared to traditional manufacturing methods.

The **durability** of PM-produced components is also notable. This process can achieve a level of uniformity in material density that is difficult to match with conventional methods. This uniform density ensures that parts are less prone to defects such as voids and inclusions, which can compromise the material’s integrity over time. As an inevitable result, components can better withstand the rigors of daily use and harsh environments, translating to longer service life and reduced maintenance costs. In essence, the process significantly minimizes the risk of component failure, a critical factor in safety-critical applications. It’s all about making parts that can go the distance, much like How Powder Metallurgy Helps magnacut Steel Achieve Superior Performance in highly demanding environments.

Another compelling benefit of powder metallurgy is its flexibility in creating complex shapes that would be challenging or impossible to achieve with traditional machining. this capability not only allows for more efficient use of materials but also opens the door to innovative design possibilities. The precision with which PM can create components is unparalleled, offering design engineers the freedom to push the boundaries in developing parts that are both lightweight and strong. This innovation is particularly beneficial in the aerospace and automotive industries, where reducing weight without compromising strength is a constant focus. In the context of How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance, PM ensures that the steel can be shaped into intricate forms that enhance its functionality without sacrificing its inherent strength.

Beyond strength and durability, powder metallurgy also contributes to **cost-effectiveness**. While the initial setup for PM might be higher, the ability to mass produce high-quality parts with minimal wastage ultimately leads to reduced production costs. This is especially true when producing intricate shapes or when dealing with expensive materials, as the reduction in scrap and the near-net-shape capability of PM can lead to significant cost savings. For manufacturers, this means a more efficient process with a healthier bottom line. Moreover, the sustainability aspect of PM, with its reduced material waste and energy inefficiencies, aligns well with the growing demand for environmentally responsible manufacturing practices, as seen in how Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance while maintaining a sustainable production approach.

powder metallurgy offers a unique blend of strength, durability, and flexibility that is unmatched by traditional manufacturing methods. its ability to precisely control material properties, produce complex shapes, and minimize waste makes it an invaluable tool in the production of high-performance materials and components. Industries seeking to innovate and improve the reliability of their products are increasingly turning to PM to meet these demands. The process not only meets but frequently enough exceeds expectations in performance and efficiency,much like How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance in demanding applications. by embracing PM, manufacturers can ensure that their products are not only strong and durable but also cost-effective and environmentally friendly.

Comparing Traditional vs.Powder Metallurgy Methods in Steel Production

In the realm of steel production, the choice between traditional methods and powder metallurgy can significantly influence the final product’s characteristics. The conventional processes involve melting, casting, and extensive mechanical working. These steps, while time-tested, have certain limitations, particularly in achieving uniform microstructures and specific mechanical properties. Conversely, powder metallurgy offers a distinct approach. It involves compressing powdered metal and heating it to bond the particles. This method can yield unique benefits, especially in the production of specialized steels like Magnacut. How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance is evident in its enhanced wear resistance and toughness compared to traditionally produced counterparts.

Traditional steelmaking methods rely on achieving desired properties by manipulating the alloy composition and using heat treatments. While effective, these processes can introduce variability due to factors like cooling rates and impurities. In contrast, powder metallurgy provides tighter control over the alloy’s composition and microstructure. The process begins with creating a fine metal powder, which is then compacted under high pressure.This compact undergoes sintering, where it’s heated below its melting point to form a solid piece. **Powder metallurgy** ensures each particle contributes uniformly to the final product’s properties, addressing issues like segregation that might occur in traditional methods.

Moreover, the environmental advantages of powder metallurgy are compelling.The method generally consumes less energy, as it eliminates several steps involved in conventional steelmaking. this is partly due to the near-net-shape capability of powder-forged parts, reducing waste and the need for extensive machining.Additionally, the controlled atmosphere during sintering minimizes oxidation and other unwanted reactions. These factors play a crucial role in How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance, particularly in sustainability aspects, aligning with modern manufacturing’s green initiatives.

another notable distinction is the flexibility powder metallurgy offers in material design. By varying the powder’s composition, manufacturers can produce alloys with tailored properties that might be challenging to achieve through traditional methods. This opens doors to innovations in steel compositions that enhance performance metrics like corrosion resistance and thermal stability. For Magnacut steel, this translates to a superior alloy that not only meets but exceeds performance expectations in demanding applications. How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance is evident in its ability to cater to specific demands that traditional methods might struggle to fulfill.

- consistent microstructure

- Reduced material wastage

- Enhanced alloying capability

- Improved environmental footprint

The economic implications of choosing one method over the other are also significant. Traditional steelmaking frequently enough involves higher costs due to the extensive energy and labor requirements. However, powder metallurgy can be more cost-effective in the long run, especially when producing small to medium-sized batches of specialized steels. The reduced material costs and energy savings can offset the initial investment in powder metallurgy equipment. When considering How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance,the economic benefits cannot be overlooked,particularly for industries seeking efficiency and cost reductions without compromising quality.

while traditional methods have their place in steel production, the advantages of powder metallurgy are undeniable, particularly for advanced steels like Magnacut. By offering control over microstructure,reducing environmental impact,allowing for customized alloy compositions,and providing economic benefits,powder metallurgy stands out as a transformative approach in modern metallurgy. As industries continue to push the boundaries of material performance, understanding How Powder Metallurgy Helps Magnacut steel Achieve Superior Performance becomes not just an academic exercise but a practical guide to achieving excellence in steel manufacturing.

Real-World Applications: Where Magnacut Steel Shines

When we delve into the transformative world of Magnacut steel, it’s essential to consider the remarkable impact it has had in various real-world applications. From outdoor enthusiasts to culinary professionals, this innovative material showcases a unique blend of strength, corrosion resistance, and edge retention.One might wonder, how can a single steel variety become a game-changer across such diverse fields? The answer lies in understanding How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance. By harnessing this advanced metallurgical process, Magnacut steel offers unparalleled performance attributes, making it a prime choice for those who demand reliability and durability in their tools.

In the realm of outdoor and survival gear,magnacut steel has quickly earned its place as a preferred material for knife blades. whether you’re a hiker, camper, or a wilderness survivalist, the need for a dependable knife is paramount. Magnacut steel provides the perfect balance of toughness and edge retention, ensuring that a blade remains sharp even after extensive use. This is crucial when you’re miles away from civilization and need tools that won’t fail you. Furthermore, its corrosion resistance means that you won’t have to worry about rust, whether you’re crossing a humid rainforest or navigating a saltwater environment. The synergy of attributes in Magnacut steel is a testament to How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance, offering blades that perform exceptionally in the harshest conditions.

In the culinary world, chefs are constantly on the lookout for knives that provide precise cuts and maintain sharpness over time. Magnacut steel has found its niche in professional kitchens, where it is esteemed for its ability to deliver razor-sharp cuts consistently. This is particularly beneficial for chefs who demand precision for everything from delicate slicing to robust chopping tasks. The ease of maintenance, courtesy of its corrosion resistance, ensures that these knives endure the rigorous demands of a bustling kitchen environment. The culinary sector appreciates How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance, giving chefs tools that enhance their culinary artistry while standing up to the wear and tear of daily use.

Beyond these practical applications, Magnacut steel’s aesthetic appeal cannot be overlooked. Knife makers and artisans are drawn to its versatility and distinctive finish, which allows for creative expression in the form of custom knife designs. The fine grain structure, achieved through powder metallurgy, lends itself to intricate patterns and etchings, providing both beauty and functionality. The customizable nature of Magnacut steel, coupled with its superior performance, makes it an attractive option for those who value not only utility but also the artistic aspect of their tools. This highlights How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance by enabling the creation of blades that are as visually striking as they are effective.

It’s also worth noting the impact of Magnacut steel in industrial applications,where high performance is non-negotiable. Whether in the form of cutting tools or machine components, this steel’s durability and wear resistance make it ideal for industries that operate under strenuous conditions. The enhanced mechanical properties, stemming from How Powder Metallurgy helps Magnacut steel Achieve Superior Performance, result in tools that have a longer lifespan, reducing the frequency of replacements and maintenance costs. This tangibly improves efficiency and productivity, making Magnacut steel an invaluable resource in the industrial sector.

Magnacut steel’s capabilities extend into the realm of scientific equipment, where precision and reliability are of utmost importance. In laboratories and research settings, cutting instruments made from this exceptional material ensure that samples are prepared with exactitude, facilitating more accurate results. The corrosion resistance and enduring sharpness of Magnacut steel contribute to the integrity of scientific investigations. As technological advancements continue to accelerate, the role of this unique steel becomes increasingly crucial, demonstrating once more How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance in environments where every detail matters.

Tips for Choosing the Right Steel: What to Consider for Maximum Performance

When selecting the ideal steel for your project, understanding its properties and how they align with your goals is paramount.Different types of steel offer unique benefits,and deciding on the right one can make a significant impact on performance. Here are some critical factors to consider:

- Strength and Hardness: Depending on your application, the balance between strength and hardness can be a deciding factor. While hardened steel offers resistance to wear and tear, it might not be the best choice if flexibility is a priority.

- Corrosion Resistance: If your project will expose steel to harsh environmental conditions, corrosion resistance becomes crucial. Stainless steel options, for example, are known for their ability to withstand rust and corrosion.

- Temperature Resistance: For applications involving high or low temperatures, choosing a steel variant with the necessary temperature resistance ensures longevity and stability.

Understanding the manufacturing process can also guide your choice. For instance,How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance by providing a uniform microstructure and consistent quality is a key consideration. This manufacturing technique allows for precise control over the material’s properties,enhancing its mechanical performance.

Another aspect to focus on is the steel’s workability. Depending on whether you’ll be welding, machining, or forming the steel, the ease with which it can be manipulated without compromising its properties is vital. Steel that is easy to machine might not hold up as well to welding, so understanding the trade-offs is necessary.

The cost of steel is also a factor that should not be overlooked. While it might be tempting to go for the cheapest option, more expensive steel types often offer superior quality and performance, which can be cost-effective in the long term. Investing in steel that better suits your project’s demands can lead to savings on maintenance and replacement costs.

Environmental impact and sustainability are increasingly important considerations. Opt for steel that is manufactured using eco-friendly processes and materials. Many steel producers now offer options that are both high-performing and environmentally responsible. Moreover, consider how How Powder Metallurgy Helps Magnacut Steel Achieve Superior Performance in a sustainable manner by minimizing waste and energy consumption.

Lastly, consulting with experts or conducting research on industry-specific recommendations can provide valuable insights. Industry standards and certifications can also serve as indicators of quality and reliability. By aligning these factors with your project goals, you can make an informed decision that ensures maximum performance and durability.

Final Words

powder metallurgy has revolutionized the production of Magnacut steel, enhancing its performance with superior wear resistance, toughness, and corrosion resistance. This innovative process allows for precise control over the alloy’s microstructure, resulting in a steel that meets the demanding needs of various industries. As technology advances, the synergy between powder metallurgy and materials like Magnacut steel underscores the potential for future innovations that push the boundaries of what’s possible in metal performance. Whether in cutlery, aerospace, or other high-performance applications, the possibilities are exciting and boundless.